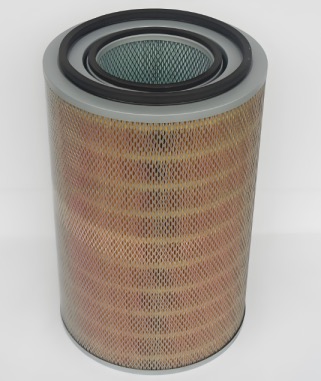

Against the backdrop of growing demand for industrial automation and precision manufacturing, CH Machinery Equipment, a leading domestic intelligent equipment enterprise, has officially released its latest developed Filter End Cover Gluing Machine. Centered on high-precision gluing technology and intelligent control systems, the equipment redefines production efficiency and quality standards for filter manufacturing. It not only applies to traditional filter element gluing scenarios but also integrates functions of Y-type End Cover Gluing Machine and Filter Gasket Pouring Machine through modular design, providing one-stop solutions for automotive, environmental protection equipment, and other fields.

High-Precision Gluing: Millimeter-Level Technology Empowers Industrial Upgrading

In traditional filter production, the uniformity, glue volume control, and sealing performance of end cover gluing directly affect product lifespan and performance. The Filter End Cover Gluing Machine by CH Machinery Equipment adopts an independently developed dynamic servo control system, combined with high-precision visual positioning technology, achieving a breakthrough with gluing path error ≤ 0.05mm. Through a multi-axis linkage mechanism, the equipment can automatically adjust gluing speed and pressure according to different specifications required by End Cap Gluing Machines, ensuring the consistency of glue layer thickness reaches over 98%.

Notably, the equipment has particularly optimized the process adaptability for Y-type End Cover Gluing Machines. Its patented rotating gluing module can accurately cover the complex structures of special-shaped end covers, avoiding common issues like glue leakage and bubbles in traditional equipment. In filter element gluing scenarios, the Filter Element Gluing Machine module uses a closed-loop feedback system to real-time monitor glue consumption and automatically compensate, significantly reducing material waste and improving production yield.

Intelligent Control and Monitoring: Data-Driven Quality Revolution

Another highlight of CH Machinery Equipment’s Filter End Cover Gluing Machine lies in its full-process intelligent management and control. Equipped with industrial-grade IoT modules, the equipment seamlessly connects with MES systems, enabling real-time upload of production data and remote monitoring. Operators can adjust process parameters for Filter Gasket Pouring Machines remotely through a cloud platform and obtain key information such as equipment operation status and fault warnings.

In the quality control link, the equipment integrates an AI visual inspection system that performs 360° dead angle – free scanning of glued end covers, automatically identifying defects like glue seam width and broken glue with a detection accuracy of 0.01mm. Combined with a big data analysis model, the system can also predict the trend of glue viscosity changes, optimizing process settings for End Cap Gluing Machines in advance to ensure long-term stable sealing performance. Additionally, the equipment supports fast switching of multiple formulas to meet small-batch and multi-variety production needs, further shortening product delivery cycles.

Market Prospect: Reshaping Industry Ecology with Innovative Technology

With the explosive growth of new energy vehicle and industrial filter markets, the demand for efficient and intelligent gluing equipment continues to rise. The Filter Element Gluing Machine by CH Machinery Equipment has reached cooperation with multiple leading enterprises, thanks to its advantages in high precision, flexibility, and intelligence. For example, in automotive filter production lines, the equipment has increased single-shift capacity by 40% while reducing the defective rate of gasket pouring to below 0.3% by replacing manual operations.

In the future, CH Machinery Equipment will continue to deepen the technological integration of Filter Gasket Pouring Machines, explore the application of AIoT and digital twin technologies in gluing processes, and help global manufacturing move towards the goal of “zero-defect” production.

Keywords:

Filter end cover gluing machine