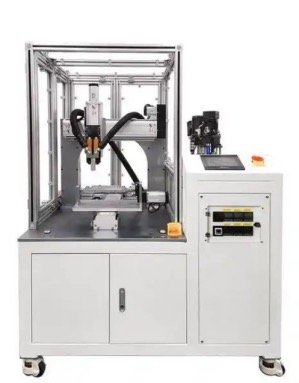

In the manufacturing field of automotive filters, the Filter end cover gluing machine ensures precise glue application and efficient sealing. Every drop of glue shoulders the heavy responsibility of safeguarding the safety of locomotives.

Technical Innovations of End Cap Gluing Machine Solve Industry Challenges

Traditional manual gluing has always been plagued by hidden issues such as uneven glue layer thickness and fluctuating curing strength. Today, the intelligent Filter element gluing machine has completely transformed this situation with three core technologies. The dynamic pressure compensation system, like a rigorous craftsman, controls the glue line thickness error within ±0.1 mm. The two-component constant-temperature glue mixing technology ensures that the AB glue mixing uniformity reaches 99.2%, increasing the curing strength by 45% and building an impregnable defense line for the filter. The nanometer-level filtration module, akin to a meticulous quality inspector, intercepts all impurities ≥5 microns, eliminating the risk of colloid contamination.

End Cap Gluing Machine Achieves Significant Cost Reduction and Efficiency Improvement

In a filter production workshop in Turkey, an End cap gluing machine equipped with a double-station circulation system is operating efficiently. It not only boosts the overall equipment efficiency to 91.3% but also achieves astonishing benefits: an annual saving of over 800,000 yuan in glue costs and a 70% reduction in labor. The application of the servo heating system has reduced energy consumption by 30%, saving over 150,000 yuan in electricity costs annually. Behind these figures lies the precise control of production costs by the Filter gasket pouring machine and its efficient utilization of resources.

Double Head End Cap Gluing Machine Reshapes Productivity Leap

In Mexican entrepreneur Grace’s intelligent gluing line for filters, the daily output has increased from 5,023 pieces to 6,811 pieces, the model changeover time has been shortened from 15 minutes to 7 seconds, the gluing cycle has been reduced from 22 seconds per piece to 8 seconds per piece, and the continuous working duration has been extended from ≤6 hours to 24-hour non-stop operation. In the Tiffany factory, the Double head end cap gluing machine seamlessly connects with upstream and downstream equipment to build an intelligent production line with balanced line rhythm. All these demonstrate the enormous potential of the intelligent Filter end cover gluing machine in enhancing productivity.

Technological Evolution Leading Future Trends

In 2024, the application of virtual commissioning technology in gluing equipment became a landmark industry transformation. The process parameter cloud library accumulates more than 300 sealant characteristic data, automatically matching temperature-pressure curves to make the gluing process more precise and controllable. The fault prediction system previews abnormal screw pump conditions through current fluctuations, advancing maintenance response by 48 hours and greatly reducing the impact of equipment failures on production. The 3D gluing simulation technology can verify the glue path design during new product trial production, shortening the trial production cycle by 65%. The control system built by Wecon PLC and HMI human-machine interface has improved the glue injection axis positioning accuracy to ±0.01 mm, achieving ultimate control over the gluing process.

With the intelligent upgrading of the automotive filter industry, the smart End cap gluing machine is becoming the core node of digitalization in filter factories.

Keywords:

Filter end cover gluing machine