The principle of filter paper flattening machine

The Automatic servo folding machine is an important equipment used for producing filter cartridges. People who have seen it find it amazing. How does it turn paper into a filter cartridge? The working principle here is what we will learn in this article, and we will also learn the precautions for operation, so that we can better use this device during the operation process.

1. In general, we divide the Filter paper folding machine into four major systems: Feida system, runway system, folding forming system, and book receiving system.

2. The Feida system consists of a fan and a paper suction Feida head. The fan has two outlet ports, and the wind speed can be adjusted by an air valve. There are two air filters on the side of the fan.

3. The Feida head mainly sucks up paper by suction and only sucks one paper at a time, and then uses a suction wheel to feed the paper into the runway, allowing the paper to begin its magnificent transformation.

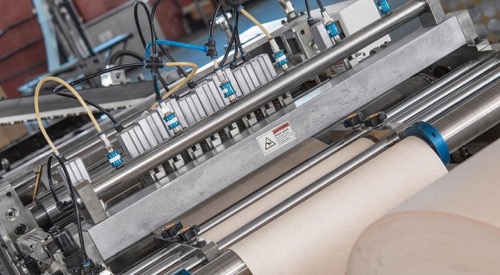

4. The runway system uses a rotating shaft to drive belts, and through this operation, paper is conveyed. There is a row of paper pressing balls above each conveyor belt.

5. The function of the paper press ball is to press down on the paper, making it smoother on the track and avoiding the phenomenon of paper deviation.

6. The folding forming system is the result of the combination of folding discs and rubber rollers, where the paper achieves the specified folding effect.

7. Up and down knife folding is mainly achieved by using paper to sense the electric eye, and then the up and down knife movements to achieve the folding purpose.

8. The book receiving system receives folded paper through a conveyor belt, allowing the paper to be neatly and orderly stacked together.

Precautions for operating a filter paper flattening machine

1. If the Filter paper folding machine cannot start and operate normally, it should be checked whether the power and safety switches are all turned on and whether normal power supply has been restored.

2. If the folding knife cannot be lowered, check whether the induction eye is damaged and whether the folding knife switch is turned on.

3. If the tension of the conveyor belt is uneven, or if the belt interface is uneven or has cracks, it will affect the conveying effect of the film paper.

4. If the paper is uneven, it may collide with the knife or pull gauge. If you find any unevenness in the paper during loading, you can flatten the edges of the paper beforehand to prevent it from being skewed during feeding.

5. Paper that has not been fully inserted into the folding tray or has curled corners can cause paper blockage, so it is important to pay attention to checking when installing and placing paper.

6. Strictly follow the maintenance regulations of the Automatic knife flapping machine, and it is strictly prohibited to knock, hit, or smash the equipment. Carefully carry out equipment maintenance work.

The analysis of the principle of Filter paper folding machine can start from the work of each link, mainly including the flying system, runway system, folding forming system, and book receiving system. When operating, attention should be paid to the power supply of the Automatic knife folding machine, the installation of the Automatic knife folding machine, and the installation of the paper, so that the Automatic knife folding machine can work normally.